What Safety Measures Should Be Paid Attention To During Waterjet Cutting

Note one

Water jet cutting is a kind of metal cut with an ultra-high pressure water jet as the medium. Its strong cutting ability and cutting adaptability are the main aspects that attract consumers. It should be known that water jet cutting is also a non-thermal effect process, which not only causes deformation but also obtains a smooth cutting surface.

Note two

As an ultra-high pressure device, the water jet itself is strictly sealed and protected to prevent high-pressure safety reasons. However, in practical applications, operators must also keep in mind the details of safe use to avoid malfunctions and other undesirable phenomena.

Note three

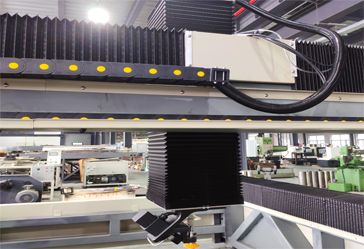

The water jet cutting process mainly relies on the movement of the CNC cantilever or gantry to drive the movement of the cutting head. Therefore, do not approach the CNC cantilever to avoid accidental injury. Similarly, avoid interference around the cantilever beam of the water jet, so as not to affect the cutting quality.

Note four

For the entire water jet, the water jet head is the outlet for high-pressure water. It is the part that directly interacts with the material during the cutting process. Therefore, it is necessary to ensure that the cutting material has been placed flat. Otherwise, the cutting sand pipe is easily damaged. High-pressure water leaks, causing personal injury.

Note five

When the water jet cutting is completed, remember to turn off the high-pressure water switch first, or turn off the high pressure before reclaiming the material. Especially during an emergency power failure, high-pressure water will still remain in the high-pressure system. Once the call is received, the remaining high-pressure water will be ejected, so do not approach the cutting head at this time. After turning on the power of the water sprayer again, the remaining high-pressure water needs to be removed for normal operation.

Note six

High-pressure pipes and superchargers are also very critical equipment for water jets, but they are also vulnerable parts that can easily cause high-pressure water leakage. Therefore, it is necessary to regularly replace its sealing components in accordance with the instructions for use. At the same time, choosing a reasonable water-cutting method is also the basis to ensure the smooth completion of the water jet cutting process.

We have a waterjet cutting machine. The waterjet cutting machine is a cutting device that uses ultra-high pressure water jets to perform the cold cutting. It is mainly composed of a high-pressure pump, a CNC machining platform, a jet cutting head, a sand supply system, and a cooling system.

The application range of waterjet is very wide, from metal materials to non-metal materials, from natural materials to artificial materials, from food to daily necessities, basically can cut, and it is known as the "universal cutting machine".

We are waterjet cutting machine suppliers. Please feel free to contact us if you are interested in our products.