5 Ways To Improve The Productivity Of The Workshop With Water Jet Cutting Machine

The workplace is a highly competitive environment. Customers expect a very fast turnaround time and flexibility to adapt to their changing needs. In order to be successful, workplaces must invest in technology to give them a competitive advantage in the market. The water jet cutting machine improves the productivity of the workshop and helps them provide customers with quality services. They reduced rework and waste and improved the work process and efficiency of the workshop.

Water jet cutting machines use high-pressure water to cut various material types. An abrasive material (garnet) is usually added to the water to increase the cutting strength.

The following are 5 ways that water jet cutting machines can improve the productivity of the workshop:

1. No rework required

Many technologies such as milling, laser cutting, and plasma cutting require rework. Some of them generate high temperatures, leading to a heat-affected zone (HAZ) on the workpiece. The burn marks on the surface of the material must be removed, which adds an extra step to the manufacturing process. Waterjet cutting does not generate heat, so this rework is bypassed and production time is reduced.

Certain machining techniques will deform the surface of the material, which must be cleaned up by deburring. Edge control uses water jet cutting to produce a smooth surface to bypass another rework step and further reduce production time.

2. Reduce waste material by nesting

Nesting is the process of arranging the contours of parts in the optimal configuration on the surface of the raw material. The accuracy of water jet cutting allows the parts to be arranged very close to each other, thus minimizing waste. By reducing waste, water jet cutting saves unnecessary costs in your workshop.

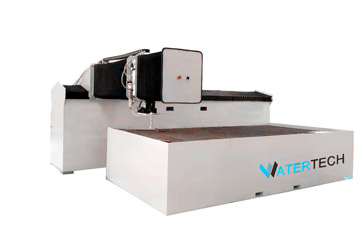

Water Jet Cutting Machine

3. Make your own components

Contracting out subassemblies puts your production schedule and quality in the hands of the supplier. You become dependent on their progress and quality performance, which may have a negative impact on your customers. The water jet cutting machine gives you the technical ability to manufacture your own components. This means that you have to control the quality of your work and the progress of delivery to provide the quality service your customers are expecting.

4. Cut several layers at once by stacking

The water jet cutting machine can penetrate through very thick pieces of raw materials. This opens up the possibility of stacking and cutting raw material sheets in a single pass through the machine. Stacking raw materials for mass production of parts can give your workshop a step-change improvement in production time.

5. Water jet cutting machine has reliable performance and easy maintenance

Job shops need the high availability of their machines to ensure maximum productivity and the ability to meet customer plans.

We are a water jet machine manufacturer. Please feel free to contact us if you are interested in our products.